AI, blockchain, IoT, Big Data… the 4th Daher Innovation Day celebrates and showcases real-world achievements based on these disruptive technologies that are accelerating the digital transformation of the Group and boosting its operational performance. The day also includes Daher long-term performance research projects: the hybrid aircraft of the future, thermoplastics, reusing production waste, etc.

Innovation Day brings Daher customers, partners and teams together to provide an overview of those projects and achievements that best reflect the dynamic commitment to innovation that has been integral to Group DNA throughout its history.

This year, the event was hosted at the iconic Tremblay-en-France hub, the newest showcase of Daher logistics expertise, tech advances and innovation capability. Outstanding in terms of its environmental qualities, this logistics hub has been designed around the principles of Lean Manufacturing with a high level of automation – centralized management resources, automated guided vehicles (AGVs), automated vertical storage systems, etc. – that optimizes its operation to meet the high expectations of our customer – a major aerospace company – in terms not only of performance (AOG[1] within two hours, for example) and employee and component safety (around 70,000 component types and a total of more 5 million components held).

Combining conferences with demonstrations, Innovation Day is a unique opportunity to explain and demonstrate how Daher is implementing a broad range of innovative technologies to improve its productivity, competitiveness and operational efficiency in ways that allow it to deliver more value to customers. The day alternates expert insights with customer feedback and live demonstrations around the central structural issues of the Daher innovation strategy: deep tech (disruptive innovations), automation, digitalization, data analytics, R&T and intrapreneurship.

Innovation Day is our annual innovation event. It provides a very special opportunity to interact in ways that raise awareness of our short-term and long-term innovation challenges and integrate them into our culture. The day is always hosted by one of our operational facilities to showcase our manufacturing and technological expertise. It includes pitching sessions and innovation project demonstrations in an environment that brings together customers, operations and partners to meet, interact, discover and share the issues that are shaping Daher today and tomorrow!

Stanislas Borowski, Head of DaherLab

Making tech concepts an operational reality

Daher has always made innovation central to its development. The Group is now pioneering Logistics 4.0 with front line implementation of technology concepts showcased and highlighted at the Innovation Day event:

- blockchain to ensure security and provide global visibility of the complex worldwide aviation industry supply chain, starting with that for our own TBM aircraft,

- AI to optimize the storage spaces of the ITER project – Meccano on the planetary scale,

- and the smart use of collected data (data analytics) to maximize solutions already deployed (IoT, etc.) and improve supply chain management.

To set the digital benchmark for its markets – one of the three cornerstones of its 2018-2022 strategic plan – Daher is also focusing on building the skills of its teams. In its workshops and logistics hubs, this means automating low value-added tasks to make the work of tradesmen and operators easier and safer, allowing them to refocus on their core tasks.

- The driverless (AGV) forklift trucks and inventory by drone solution showcased at Innovation Day are all part of this structure,

- as is the use of AI to automatically detect correct wearing of personal protection equipment (PPE),

- the use of a mobile app to deliver dynamic interactive instructions to carry out a series of tasks that improve operator productivity, quality and safety,

- and a virtual reality simulator employees can use to train themselves in forklift truck driving.

360° innovation

Detected and tested by two agile structures – the Armstrong by Daher program based in Silicon Valley and the DaherLab in France – technologies make the transition from concept to industrial implementation within a few months in accordance with a proven process – from PoC (Proof of Concept) to rollout – developed and tested with input from operations staff and substantial support from the dedicated Digital Accelerator IT team. The innovations showcased at the Innovation Day event highlight the effectiveness of this methodology, introduced by DaherLab nearly four years ago.

These technologies enable Daher to develop new skills, new offers and new products based on its dual expertise as a manufacturer and logistics expert/service provider. This unique positioning at the point where manufacturing and services converge sets us distinctively apart from the rest of the market, and allows us to test and prove the validity of our innovations end-to-end at every link in the aviation industry value chain, from design to production, supply chain and maintenance.

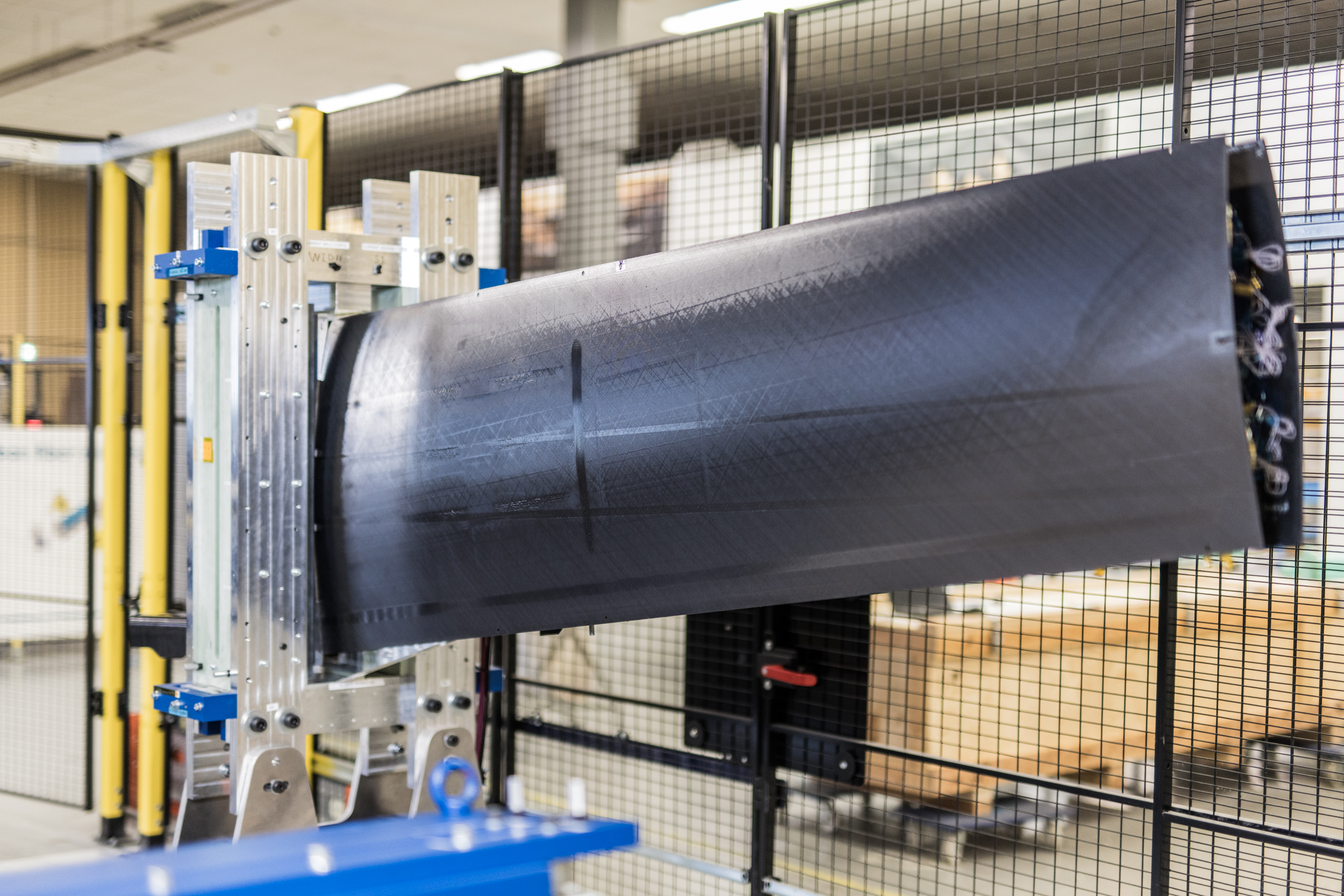

Our strategic investments in R&T give us the ability to design innovative products, perfect future processes – such as automatic thermoplastic fiber placement – and position ourselves as a high value-added partner. Our ambition is to develop alternative ranges that will allow us to manufacture lighter, low-cost structures that meet the profitability and productivity needs of aircraft manufacturers.

DOMINIQUE BAILLY, HEAD OF R&T

It is also what makes Daher a long-term leader in the industry of the future; a responsible and committed stakeholder in major collaborative projects that will reduce the environmental impact of air travel.

The fact is that at Daher, we have adopted a 360° attitude to innovation. It combines the short lead times made possible by open innovation alongside our teams, customers and partners (startups, academics, etc.) with the longer timescale of R&T and its – usually collaborative – large-scale projects in ways that allow us to design distinctive, competitive solutions and tomorrow’s manufacturing processes over timescales of between 3 and 10 years. Our Innovation Day event presents several of them, each sharing the same ambition to meeting the central challenges faced by the aviation industry: speed of throughput, competitiveness and reducing the environmental impact of aircraft.

In this respect, Daher is a major force in thermoplastics, whose use makes aircraft lighter, thereby reducing fuel consumption and in-flight emissions, at the same time as increasing production throughput using automation.

A number of demonstrators – which Daher is able to test on its own TBM aircraft, giving it an advantage unique in the market – are being showcased today, including a large thermoplastic wing rib (which delivers a weight saving of just over 35% at the same cost as aluminum) developed as part of an innovation program led by the French Civil Aviation Research Council (CORAC). Other stars of the day include the EcoPulse project unveiled at this year’s Paris Air Show to create a hybrid aircraft demonstrator currently being designed with Airbus and Safran, and a project to repurpose thermoplastic production offcuts as the basis for producing a high-performance material with aviation applications.

Daher contributes to many collaborative R&T projects through its membership of the French Civil Aviation Research Council (CORAC). Our TBM aircraft gives us a unique experimentation and demonstration platform that we are able to share with our partners in general and other aircraft manufacturers in particular. We have the ability to conduct small-scale testing of new technologies and their potential for certification as the basis for our customers to assess the feasibility of scale-up for their own programs. And the same is true for engine manufacturers…”

Sébastien Leroy, CORAC Program Director, Daher

Ensuring a long-term future, continuing to grow, winning new markets and looking to the future all require the ability to stand out distinctively from competitors and innovate successfully. With its pioneering spirit and long-term vision, Daher is more focused than ever on near-term and long-term innovation to accelerate its transformation, deliver it successfully and become even more competitive and efficient for the benefit of its customers.

[1] Aircraft On Ground (AOG): emergency response service that enables a grounded aircraft to depart