Paris Air Show, Le Bourget, France, June 20, 2023

At the 54th Paris Air Show, the Daher Group today confirmed its objectives for the future – backed by a commitment to quadruple its research & development investment with the goals of decarbonizing its business activities and those of its customers.

Decarbonization: a priority challenge

Daher, which celebrates its 160th anniversary this year, has placed the “innovation to decarbonize” at the heart of its “Take off 2027” strategic plan unveiled at the start of 2023.

Present throughout the aeronautics value chain with its 4 complementary businesses – aircraft manufacturer, manufacturing, industrial services and logistics – Daher intends to make a significant contribution to the efforts of the entire industrial sectors in which it is present. The company’s objectives already have translated into a strong investment in R&D projects, the budget of which has quadrupled since the previous strategic plan.

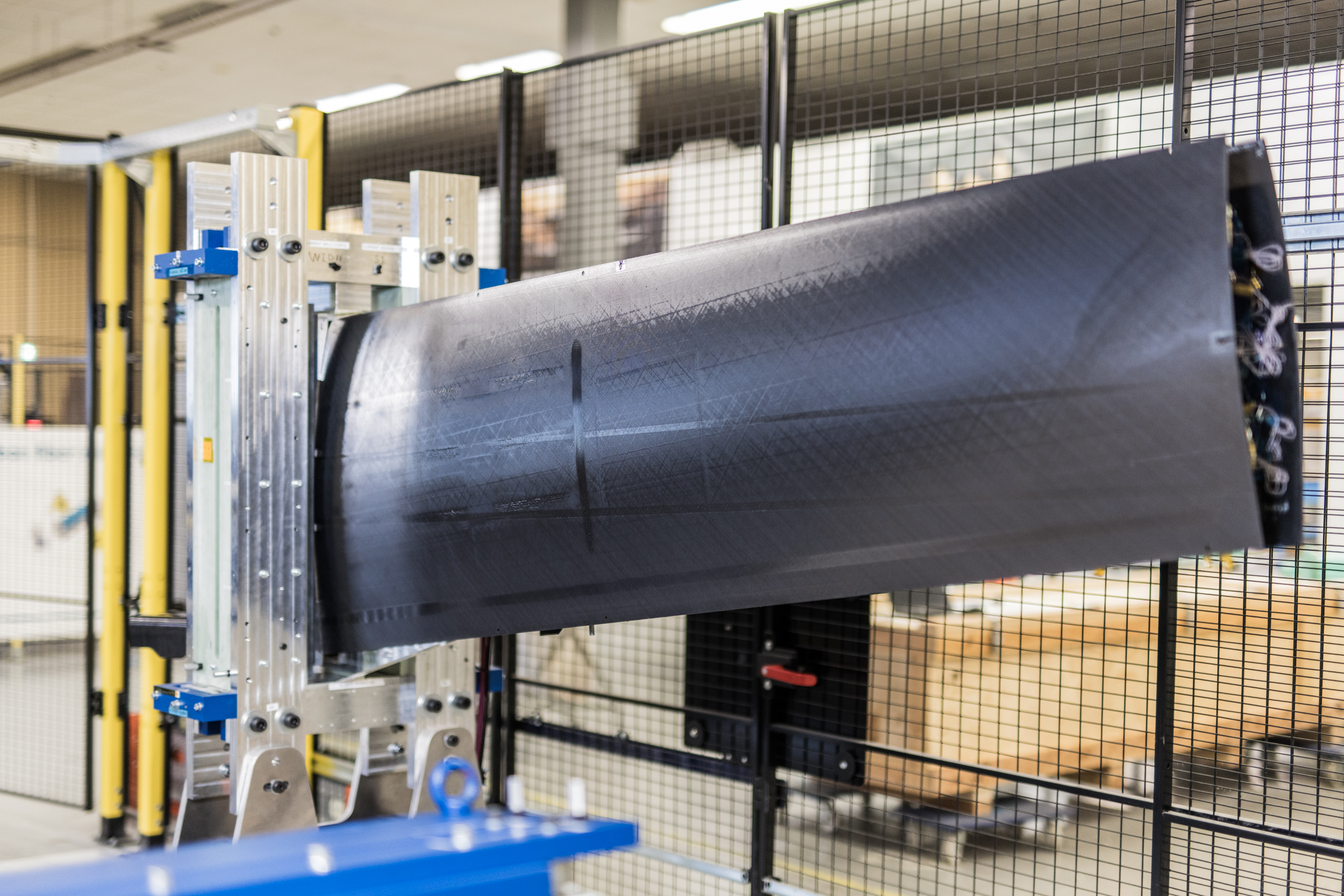

To accelerate even further, Daher has set up three innovation centers: Shap’in, for the design of lighter, more efficient and recyclable aeronautical structures; Log’in, to reduce the environmental footprint of industrial logistics; and Fly’in, dedicated to the hybrid and carbon-free aircraft of tomorrow.

The idea is to contribute – hand in hand with partners, customers and startups – to the design of solutions leading to a “Net Zero” impact by 2050, with a first significant step from 2035, aligned with the Paris Agreement on climate change.

The three innovation centers combine:

- The inherently long-term outlook of R&D, with its large-scale projects – most often collaborative – to design tomorrow’s distinctively competitive solutions over a timescale from 3 to 10 years: hybridization, new-generation materials, production processes (robotization, cobotization, etc.) and digital transformation (Supply Chain 4.0, digital factory, etc.)

- The short-term of open innovation, which is based on expertise sharing and collaboration with our teams, customers and innovative ecosystems and players (academics, manufacturers, startups, SMEs, etc.) to accelerate the innovation process.

This 360° approach responds simultaneously to:

- The decarbonization challenges faced by customers(90% of the group’s carbon footprint):

– Lighter structures, new production processes to meet the twin challenges of higher output and the reduction of carbon emissions, etc.

– More eco-responsible logistics (digital twins to optimize flows, “cleaner” modes of transportation, use of biofuels for its truck fleets, optimization of storage space, etc.)

- The determination to decarbonize the Group’s own activities and products

– The launch of a hybrid-electric aircraft as early as 2027, whose development will be based in particular on the lessons learned from the EcoPulse project run in partnership with Safran and Airbus with support from the French government via the “France Relance” national recovery plan, and the European Union via its NextGenerationEU initiative. Daher is working along with Safran and Airbus on the development of EcoPulse, a demonstrator aircraft with hybrid-electric propulsion.From this demonstrator program, Daher plans to develop its future product roadmap and establish the specifications of the hybrid aircraft that will be offered on the market by the end of 2027;

– Reduction of emissions from its own operations (energy consumption in buildings, the use of biofuel for its transportation fleets, recycling, etc.)

Daher also uses the digitalization and intelligent management of its activities to reduce its environmental footprint

- Smart logistics management at its different industrial sites using the INES solution from French startup DCbrain – a specialist in artificial intelligence applied to the supply chain;

- The use of a digital twin (JUMEL) to model and optimize logistics warehouses – a project led by the Log’in Techcenter to promote and facilitate innovative, eco-responsible industrial logistics

- Digitalizing the collection, processing and analysis of data from the TBM turboprop-powered aircraft for more responsible flying (Me & My TBM app)

According to Didier Kayat, the Daher CEO: “We are participating today in the fourth revolution in aeronautics; after the first flights, safety and the democratization of air transportation, our new frontier is decarbonization. Since Daher’s creation 160 years ago, the company always has supported key industrial developments with its customers. We continue to write this story by going further: it is as pioneers that we will be the first to offer a hybrid aircraft to the market.”

Daher’s TBM and Kodiak aircraft families are spearheading low-carbon general aviation and benefiting from the company’s innovation, and at the service of mission-oriented aviation

Daher designs, manufactures and maintains two iconic families of lightweight, agile aircraft: the TBM and the Kodiak, at the service of more responsible aviation. Daher is convinced that aviation is an indispensable resource for performing humanitarian missions and serving the best interests of society.

These aircraft will accelerate Daher’s innovation, providing the perfect platforms to integrate new modes of propulsion and be the first in hybridization.

- The TBM pressurized single-engine turboprop, one of the world’s fastest and most efficient aircraft, and an international aviation industry benchmark.

- The Kodiak, an all-terrain and agile multi-mission aircraft, which can land and take off in short distances. In particular, the Kodiak can carry up to 9 passengers and smaller cargo payloads (1,600 kg) in conducting humanitarian and medical flights, performing civilian surveillance missions (for firefighting, urban security, and the protection of nature) as well as for military purposes; and even special operations such as the deployment of paratroopers. The Kodiak 900 – the latest member of the product line – has been aerodynamically optimized and consumes 9% less fuel than its competitors, lowering the cost per seat-kilometer and the direct operating costs for commercial operators.