At the JEC World 2024 show, Daher and its KVE subsidiary are presenting their latest R&D achievements for the next generation of aircraft. In the spotlight this year: a full-scale welded thermoplastic torsion box demonstrator, which underscores Daher’s advances and ambitions in the field of advanced composite aerostructures for the future.

The 2024 edition of JEC World will be significant for Daher in several ways. For the first time, the expertise of Daher and KVE are brought together on the same exhibit stand. And this coincides with the finalization and presentation of a major component that demonstrates the value of the collaborative approach adopted since Daher’s acquisition of the Dutch company in 2019.

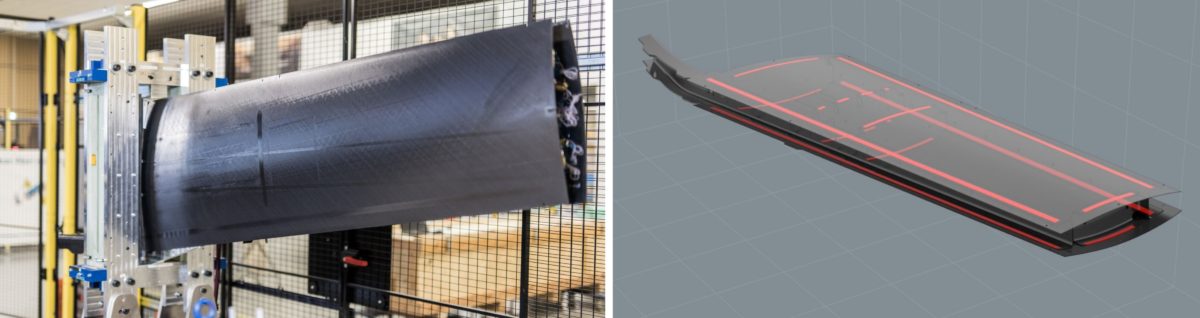

“This full-scale component represents the torsion box for the horizontal stabilizer on Daher-built TBM aircraft,” explained Dominique Bailly, Daher’s R&D Director, who also heads the company’s Shap’in innovation center dedicated to aerostructures of the future, in Nantes, France. “This demonstrator implements a set of cutting-edge processes – automated fiber placement (AFP), Direct Stamping®, co-consolidation – for manufacturing the aerostructure’s elements, as well as for its assembly that was performed utilizing KVE’s exclusive induction welding process.”

A step toward wings of the future

As a leading example of Daher’s technological advances, this demonstrator prefigures the wing elements of tomorrow’s commercial aircraft: lighter, more efficient, more eco-responsible. “Last year at JEC World, we presented a reduced-scale demonstrator that we tested mechanically, and from which we learned a lot to design and develop the full-scale demonstrator. This will now, in turn, be tested and broken… The objective is to quickly be able to submit a certification request to the competent authorities, to enable the use of revolutionary parts like this on production aircraft. Daher has the particularity – and the opportunity – to be both an aircraft manufacturer and an aeronautical equipment supplier,” continued Dominique Bailly.

Daher has placed its TBM airplane, along with the company’s aircraft manufacturing skills, at the heart of its innovation strategy. The size of the TBM as a general aviation-category aircraft, and the regulatory agility of the associated airworthiness certification category (CS 23), make it possible to position the TBM as a precursor and demonstrator of tomorrow’s technologies.

“The objective is to reach the TRL 5 maturity level[1] in 2025 after the tests, and to be ready at the TRL 6 level from 2027 to be able to integrate this type of component on existing programs. Welding – which allows us to eliminate the use of metal rivets – is of enormous interest in terms of mass, production rates and cost, as well as recycling…”

Shap’in, the technology accelerator

The replacement of metal with composite materials – thereby reducing weight – is one of the strong axes of the air transport industry’s decarbonization strategy, and is the purpose of Daher’s Shap’in innovation center dedicated to the aerostructures of tomorrow. Bringing together a concentration of expertise and resources since becoming fully operational in mid-2023, the features of Shap’in include a 1,600-square meter developmental mini-factory for composites.

With this unique resource, Daher’s research and development teams are completely independent – from layup to the finishing of parts. “As an example, we can cover the full cycle for a demonstrator component in record time: from receiving the CAD definition to manufacturing the appropriate molding or machining tools, then producing the parts, carrying out quality control, and delivering the component,” added Dominique Bailly.

Through Shap’in, Daher intends to accelerate and facilitate the use of innovative advanced materials – thermoplastic composites, first and foremost – in aeronautical programs. The Group’s materials expertise, illustrated by the R&D project CARAC TP, allows it to play an important role with customers and to be a source of recommendations on the thermoplastic and thermoset materials to be used, depending on the application. (To find out more, see the JEC World 2024 conference presentation by Stéphanie Patel, Daher’s Head of Material/Expert: “Beyond Boundaries: Composite Materials Shaping the Aerospace Industry.“)

Focused for more than 10 years on the wing and engine environment for aircraft, Daher’s technological roadmap will enable the Group to offer mature solutions that respond to the major challenges of decarbonization and attaining production rates for the next generations of commercial aircraft in the 2030-2035 timeframe.

The adopted strategy is bearing fruit

“The adopted strategy already is bearing fruit on existing programs. At this year’s JEC World show, we are presenting an internal bypass duct (IBD) made of high temperature resin (BMI carbon), which is complex to produce. This structural part for aircraft engines has been in series production for several years by Daher, and enables significant weight savings on aircraft engines – responding to a major challenge in the aeronautical sector,” added Dominique Bailly.

This success sums up Daher’s ambition to change the dimension in terms of production of composite parts. To achieve this, the Daher Group benefits from a dedicated factory – the largest in Europe devoted to thermoplastic composites, with nearly 300,000 basic parts produced annually – which is located in the immediate vicinity of the Shap’in technical center at Nantes.

“Mass-producing increasingly complex and structural parts by relying on existing know-how and resources, and bringing ever more value to our aircraft and engine manufacturing customers: this is the full value of the Shap’in project, as well as the collaborative approach that we continue to develop,” Bailly concluded.

[1]The TRL (Technology Readiness Level) scale assesses the maturity level of a technology. TRL 5: validation of the technology in a representative environment; TRL 6: demonstration in a simulated real environment

To know more…

Daher’s exhibit at JEC World: Hall 6, Stand C32.

Our speakers:

- Stéphanie Patel, Head of Material/Expert, participating in the conference: “Beyond Boundaries: Composite Materials Shaping the Aerospace Industry,” March 6, 2:00 p.m.-2:55 p.m., Agora 6

- Lucas Petry, Industrial Services Talent Acquisition Manager: “Come on board at Daher!” March 6, 2:00 p.m., Campus Village

Also read:

- Everything you always wanted to know about Daher and advanced composites

- Advanced composites for aerospace: how Daher is expanding the possibilities

- Daher lays the cornerstone for the Shap’In innovation center that will develop its composite aerostructures of the future

- Daher powers the take off of thermoplastics