Presentation

Specialist in optimizing and securing of flows and operations on behalf of major customers in the nuclear sector.

Daher has established itself as one of the world’s leading nuclear players for more than 30 years. Its integrated services – including engineering, project management and operations – are recognized along six lines of services. These services position Daher as a Tier 1 partner for each step of the nuclear cycle.

Our added Value

- Performance and industrial control brought together in a complementary industry and services offer with high added-value (integrated industrial systems)

- Innovation in Daher’s core business: Nuclear 4.0. (digital engineering processes, with deployment of BIM and use of a virtual reality center)

- A responsible industrial approach for the environment (control of nuclear waste and reduction of carbon impact).

-

1

dedicated technical department, 1 virtual reality center, 2 operational bases

-

20

client sites

-

17,000

cubic meters of radioactive waste from French producers treated at ICPE for safe storage at ANDRA

-

4,000

cubic meters of annual radioactive waste treatment capacity

-

10,000

radioactive nuclear transportation shipments of all categories performed in France

-

200

annual flow of projects, including 60% involving optimization of logistics and the securing of maintenance operations.

Our offer

Project management & turnkey systems

Project management & turnkey systems

– Design of nuclear installations,

– Redevelopment, improvement and life-extension for existing facilities,

– Design of complex mechanical structures.

Dismantling & remediation

Dismantling & remediation

– Dismantling, cleaning and decommissioning services,

– Characterization, measurement, sorting, repackaging and treatment of radioactive waste,

– Acceptance file at Daher’s site or at the customer’s site.

PGAC (Comprehensive site assistance services for nuclear sites)

PGAC (Comprehensive site assistance services for nuclear sites)

– Management of general stores (spare parts, tools),

– Maintenance and production logistics,

– Handling heavy loads,

– Waste management,

– Maintenance of radiation protection and environmental protection equipment.

Maintenance & operational support

Maintenance & operational support

– Maintenance of containers and equipment in operational conditions,

– Operation of facilities for third parties,

– Maintenance of packaging and related services,

– Nuclear measurement,

– Nuclear diving (hyperbaric work).

Nuclear installations

Nuclear installations

– Waste treatment and tooling maintenance (characterization, cutting, packaging),

– Maintenance of transport packaging (maintenance, safety/compliance, fleet management),

– Radiological characterization laboratory (nuclear measurements, Physico CX abalysis, ICPE self-monitoring),

– Temporary holding of radioactive “substances” (waste and materials in transit, at Daher’s transit base, in the storage yard).

Transportation

Transportation

– Transportation of contaminated tools,

– Transportation of nuclear material (fuels),

– Transportation of tanks,

– Transportation of radioactive waste, asbestos and sodium,

– ADR transportation in special convoys.

Use case

-

![]()

Remediation of the Marie Curie laboratory

Daher and its partner of reference were involved…

Daher and its partner of reference were involved in supporting the Rectorate of Créteil for the rehabilitation of the former Marie Curie laboratories in Arcueil. The company’s teams deployed innovative tools from its Nuclear 4.0 program, including a complete 3D scan of the site (stereoscopic imagery included). The realistic representation provided an intuitive environment that facilitated the decisions taken by the project manager.

-

![]()

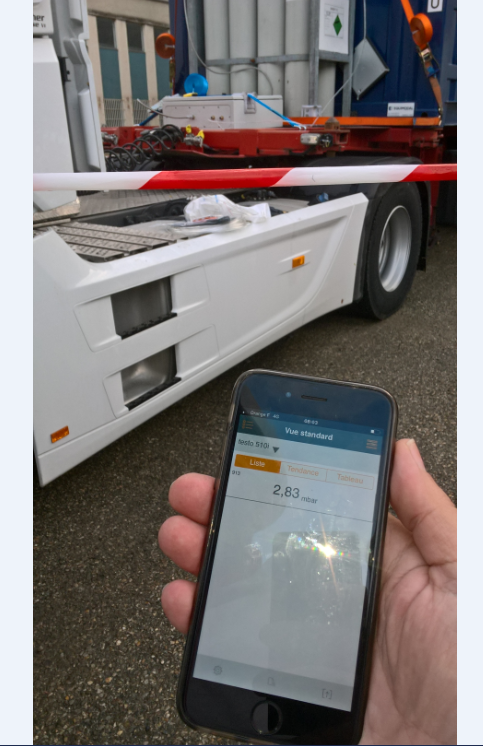

Radioactive sodium nuclear transport from the French Atomic Energy Commission’s (CEA) Rapsodie research reactor (Cadarache site) to the Phenix reprocessing facility located on CEA’s Marcoule site (Class 7 and Class 4.3 transportation)

To achieve this specific shipment, Daher developed…

To achieve this specific shipment, Daher developed a dedicated inert container. The technical department’s safety teams obtained the validation of the CEA Cadarache center’s security unit for the use of this new concept, along with the Nuclear Safety Authority’s agreement for LSA II classification of the nuclear matter. This made it possible to carry out two shipments with Type IP2 packaging.

Daher teams oversaw the system’s manufacturing and acceptance. The Daher transport office then carried out the operation successfully – and in accordance with the schedule.

-

![]()

Industrial organization and logistics for the replacement of used fuel storage racks (RSCUs) of the French National Center for Electricity Production (CNPE) at Nogent sur Seine

EDF entrusted GMEC REEL-ORYS with the replacement…

EDF entrusted GMEC REEL-ORYS with the replacement of fuel storage racks used for the combustible building’s (BK) pool in Unit 2 of the NOGENT NPP. For their respective work shares, EDF and REEL SAS assigned Daher with on-site logistics – including transport activities and certain handling operations.