A strategy driven by the Group’s values

Finding better ways of doing things so as not to compromise the capabilities of future generations, while reconciling economic and social progress with environmental protection: the challenges of sustainable development resonate particularly strongly at Daher, a family-owned company committed to the concept of responsibility, both for present and future generations.

Sustainable development is one of the cornerstones of Daher’s corporate purpose and is a collective commitment under the Take Off 2027 strategic plan, in which everyone, at their own level, has a role to play within the company.

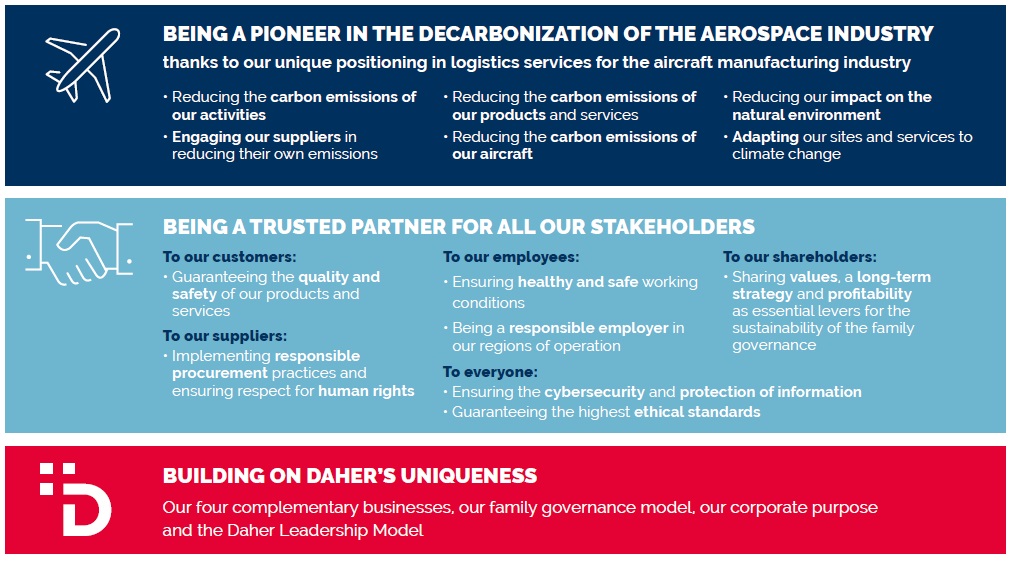

In order to structure its approach and achieve its ambitious goals, Daher has organized its approach around three pillars that bring together the priority issues identified.

Being a pioneer in the decarbonization of aeronautics

Daher has a unique position and presence across the entire aerospace value chain, from logistics to aircraft manufacturing. This gives it real strength and the ability to act at multiple levels with both its customers and suppliers. In concrete terms, the decarbonization effort is focused on three main areas:

- decarbonizing products and processes throughout their life cycle;

- reducing resource consumption

- and adapting our sites and services to climate change.

Several initiatives and actions launched in this area formalize this commitment:

- the development of the EcoPulse hybrid-electric aircraft demonstrator;

- the implementation of a thermoplastic waste recycling process in Nantes to optimize materials management and reduce waste;

- the use of sustainable fuels for our heavy goods vehicles and flight operations;

- the implementation of the 3R strategy (Reduce, Recycle, Reuse) for packaging consumables with the aim of limiting waste and promoting a circular economy;

- and the assessment of all our sites using the AXA Climate methodology to better understand their exposure to climate risks.

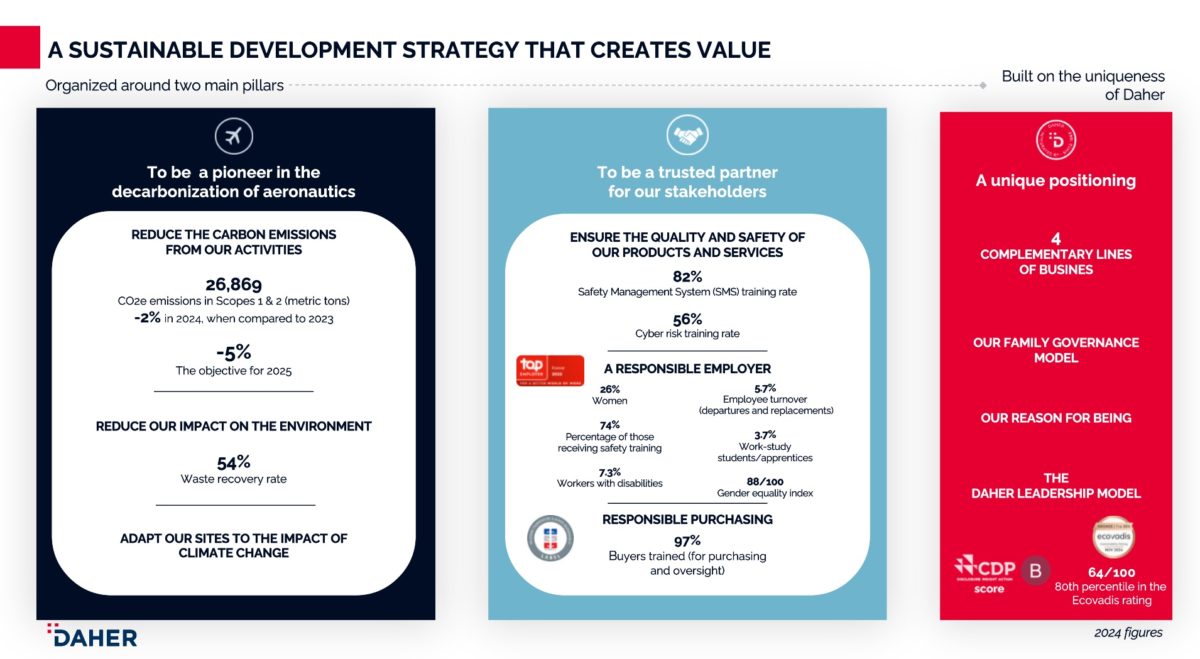

In France, CO2 emissions (scopes 1 and 2 in France) decreased by 11% in 2023 compared to 2022, reflecting efforts in the area of sustainability. Daher has set an ambitious target of reducing CO2 emissions across the entire Group by 5% per year starting in 2022.

CO2 is not the only battle to be fought: Daher’s businesses impact the environment through the waste they generate, the risk of pollution, or the use of substances that are harmful to humans and/or the planet.

Climate change is happening, and what we do today to try to minimize its impact will not be seen until 2050. Until then, we will suffer the effects with increasingly violent and/or frequent climate events. Our businesses and sites must take this into account and prepare to be resilient by adapting.

Being a trusted partner for all our stakeholders

Our customers expect us to deliver optimal quality that will ensure maximum safety for their teams, their products, and their customers. This is the foundation of our business, but also our primary responsibility.

With regard to our suppliers, we strive to build balanced and responsible relationships in order to guarantee the sustainability of our supply chain. A partnership based on rights and responsibilities to advance human rights, ethics, and environmental protection in all sectors of activity.

Above all, Daher employees must enjoy safe working conditions: their health and safety are our top priority as an employer. Every effort must be made… This is the aim of the Safety@work program, which has been strengthened in terms of ergonomics following the annual Talk’in survey on working conditions. But being a responsible employer also means knowing how to integrate, train, recognize, and share value. This is what Daher strives to do.

Finally, we have identified two major challenges that concern all our stakeholders:

- business ethics, i.e., a set of values and moral rules that apply in corporate life;

- and cybersecurity, where each of us can help build a line of defense and thus ensure our cyber resilience.

Building on Daher’s uniqueness

Our third pillar, which is more of a foundation on which we can build our sustainable development strategy, is Daher’s uniqueness, its presence in four complementary businesses in the aerospace value chain, its family governance model, its corporate purpose, and its Leadership Model, which unite and ensure collective success.

Sustainable development is one of the cornerstones of Daher’s strategy. Thanks to a clear vision and concrete actions, Daher is positioned as a trusted partner to all its stakeholders, while pursuing ambitious goals for 2027 and beyond, particularly in terms of reducing CO2 emissions and responsible resource management.

Daher shows that innovation and sustainability can go hand in hand to build a better future for all.

Read our 2024 Integrated Report

Local initiatives

AI to cut the energy consumption of buildings

AI to cut the energy consumption of buildings

Reducing the energy expenditure of logistics and industrial buildings by 15 to 25%, thanks to connected sensors and artificial intelligence, that’s the result of the Hestia project, based on the solution from the Kipsum startup.

The solution creates a digital twin of the building and an energy consumption profile based on the geometry of the site, ambient temperature and humidity, ventilation, heating settings, but also on staff usage habits. Artificial intelligence then intervenes to modulate heating, the primary energy source in a building. Energy optimization recommendations are also transmitted on a web or mobile dashboard. The tool, which has proven its effectiveness, is deployed or in the process of being deployed on several of the Group’s logistics and industrial sites.

Thermoplastics composites: 100% win-win recycling

Thermoplastics composites: 100% win-win recycling

The circular economy is an excellent way of reducing carbon footprints while ensuring greater profitability. The Saint-Aignan-de-Grandlieu plant, near Nantes, is proving this once again by recycling its thermoplastic composite production scraps. Previously buried in landfills, the five to ten tons of material annually will be crushed and granulated to manufacture new parts, such as rudder pedals. The goal is to obtain the necessary certifications to use this recycled material in other aerospace parts, among other applications…

Watch the video to learn more: https://youtu.be/I2l7QFhD08M

Mobilized to reduce consumables

Mobilized to reduce consumables

The “Reduction of consumables” challenge was enthusiastically led by our Open Innovation team in partnership with Air France Industrie (AFI). The objective was to embark on and highlight the innovative ideas and concepts of Daher and AFI employees to limit consumables, whatever they may be: paper, plastic, energy… The winner on the Daher side, out of the 23 applicants, is the Silico Presto project proposed by Nicolas Bauchet (Nantes). Its goal? Replace with silicone vacuum covers, reusable for 10 to 20 cycles, those made of plastic, used until now for oven polymerization cycles.

“Elles bougent”: the future is written in the feminine

“Elles bougent”: the future is written in the feminine

Daher signed a partnership agreement with the “Elles Bougent” (“They are moving”) association in order to strengthen the presence of women within the Group in all professions. About twenty volunteers – godmothers (women occupying an engineering, scientific or technical profession) and relays (men or women with varied profiles working in the industry) – have the mission of informing the young women of the numerous scientific and technical career opportunities available to them. The godmothers talk about their journeys, their profession, the difficulties encountered, etc.

In the Nantes, Toulouse, Tarbes and Ile-de-France areas, interventions in middle and high schools, career forums and even innovation challenges and competitions have been organized. Visits to the Daher tech centers also took place, as did targeted actions during the Paris Air Show 2025.

A cleaner truck fleet immediately

A cleaner truck fleet immediately

Daher relies on PUR-XTL biofuel to reduce CO2 emissions from its fleet of vehicles. The first 30,000-liter tank was installed at the Corlog logistics site (Toulouse) in February 2023, followed by a second at Roissy in 2024. This equipment will allow trucks to benefit from the biofuel on 100% of the Toulouse-Hamburg routes, representing 60% of the kilometers covered each year. German stations allow refueling with PUR-XTL.

2,000 tonnes of CO2: the savings expected by 2025 with the use of PUR-XTL biofuel for all routes, including Toulouse-Hamburg.