Paris, le 21 juin 2016 – Sur un marché du nucléaire en profonde restructuration, DAHER, équipementier de rang 1, mise sur l’innovation au service de la compétitivité de la filière. Pour cela, DAHER peut compter sur son expérience acquise dans l’aéronautique pour appliquer les bonnes pratiques de ce secteur d’excellence au marché du nucléaire.

DAHER propose ainsi 3 principales offres à forte valeur ajoutée : des vannes de haute performance, une gamme de services nucléaires spécifiques et des solutions logistiques clés en main. Ces offres se déclinent sur les projets neufs comme sur le parc en exploitation, ainsi que sur les installations de recherche ou du cycle. « La filière nucléaire française et européenne fait aujourd’hui face à un enjeu de profonde transformation. Notre expérience de la mutation réussie du secteur aéronautique nous apporte dans ce contexte une capacité d’anticipation. Nous nous positionnons comme un acteur clé de la transformation de la chaîne nucléaire française, avec une offre centrée sur l’optimisation du planning et du coût des projets », commente Hervé de Chillaz, Directeur de la Business Unit Technologies Avancées.Vannes : moins de maintenance pour une diminution du coût de possessionL’ensemble des centrales nucléaires françaises et une grande partie des centrales dans le monde sont équipées des vannes françaises Vanatome.

L’innovation menée par DAHER porte entre autres sur la diminution du besoin de maintenance de ces vannes permettant une réduction significative du coût de possession. Par ailleurs, l’équipementier travaille en permanence à proposer des produits toujours plus compacts, grâce à l’utilisation de nouvelles technologies et de nouveaux matériaux.Des solutions logistiques clés en main pour sécuriser les nouveaux projets et l’exploitation des centralesLa logistique et l’optimisation des flux industriels complexes sont des savoir-faire historiques de DAHER qui, dans un enjeu global de réduction de coûts, propose des prestations de Supply Chain Provider et des outils de pilotage novateurs comme la DAHER Control Room.

Ainsi depuis 2012, DAHER est Global Logistics Provider du projet ITER (la plus grande installation expérimentale de fusion jamais construite) : DAHER a la responsabilité de l’optimisation et de la sécurité des livraisons de l’ensemble des composants du projet ITER.

Ainsi, DAHER a organisé avec succès, en mars dernier, le transport d’un des plus longs éléments exceptionnels du projet : 4 poutres aux dimensions impressionnantes (46m de long pour 155 tonnes chacune) composant le pont de levage du bâtiment d’assemblage où seront préassemblés les éléments principaux du réacteur.Une offre de services spécifiques pour répondre aux nouveaux enjeux industriels du marché nucléaireOutre les services usuels de transport d’uranium, de combustibles et de déchets, DAHER propose des services nucléaires innovants et uniques sur le marché permettant un traitement optimisé de toute la gamme de déchets nucléaires, du plus faible niveau d’activité au plus élevé et complexe, et la logistique associée. Par exemple, Daher est à même de proposer des solutions combinant des opérations de tri/traitement sur site client et sur ses propres installations, ou encore de prendre en charge tout ou partie de la gestion d’effluents radioactifs qui, de par leur état liquide, imposent une maîtrise parfaite des contraintes de sureté nucléaire et une excellence en matière de transport.

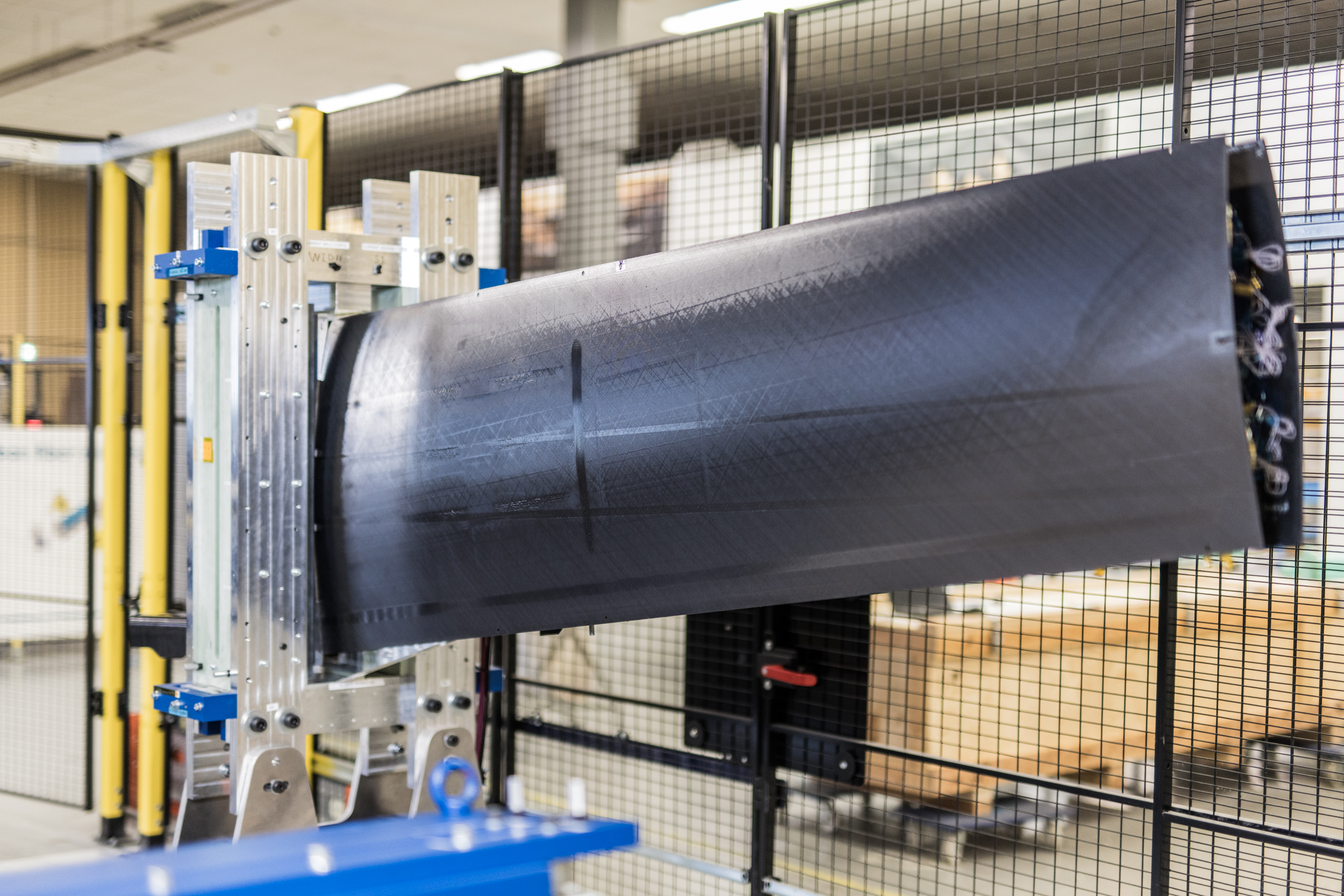

Aussi, l’équipementier est le seul acteur du marché à proposer le NCS45 qui est un produit et procédé breveté, testé et agréé d’encapsulation des crayons combustibles nucléaires endommagés, sous eau ou en cellule chaude (UBE).

Les défis du marché du nucléaire sont totalement intégrés et pris en charge par nos équipes d’experts. C’est pourquoi DAHER concentre ses efforts sur l’innovation en la plaçant au service de la compétitivité de la filière. Nous sommes à même d’accompagner nos clients à chaque étape de leur chaîne de valeur, dans leurs défis industriels pour assurer la pérennité du mix-énergétique de demain », ajoute Bruno Cahen, en charge du Développement des Services nucléaires. DAHER sera sur le Salon WNE du 28 au 30 juin 2016 Stand EB-E48/F47et animera le 30 juin 2016 à 10h30 une conférence sur « La solution DAHER clé en main pour l’évacuation de crayons endommagés ».